It’s super important to keep up with regular maintenance for your exhaust systems if you want to make sure they run smoothly and safely on heavy machinery.

Unlike some systems that have warning lights, exhausts don’t give you immediate alerts for issues. That’s why it’s critical to do regular checks to catch potential problems early, save money, and avoid future complications.

Check for signs of rust, grease buildup, or any fluids that might indicate underlying problems. Make sure all the components are aligned and functioning correctly and keep an eye out for soot or wet spots that could suggest leaks or malfunctions.

So, how can you spot exhaust system issues without relying on the dashboard light? We recommend keeping a lookout, listening, and sniffing for these 7 signs on a monthly basis.

Related article:

Inspect all clamps, mounts, flanges, and brackets

Make sure you check all the clamps, mounts, flanges, and brackets thoroughly. Look for any signs of movement or wear and if you find anything wrong, fix it immediately. This will help maintain optimal functionality and safety standards. Always be precise in your assessment to prevent any potential issues and ensure operational integrity.

Consistent attention to detail will help you build a strong system, minimize downtime and maximize efficiency. So, it’s important to keep up with regular upkeep, and make sure you and your team are diligent and accountable in your work.

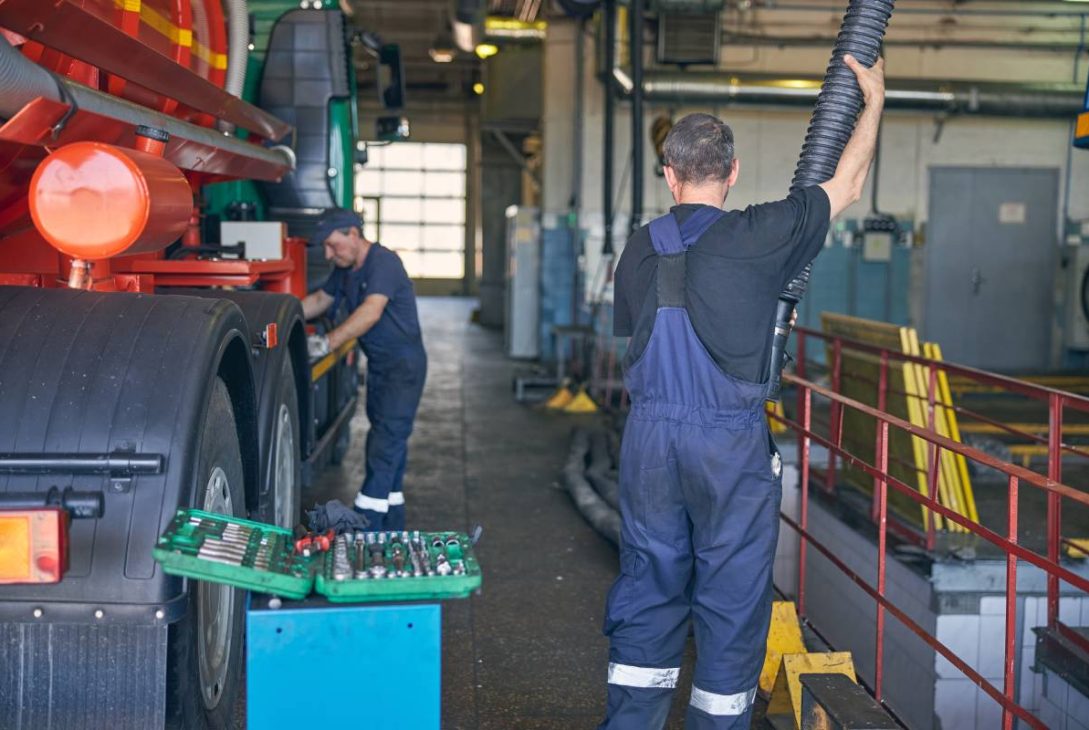

Check for exhaust soot on or around the exhaust system

Make sure to check the exhaust system thoroughly for any signs of exhaust soot on the components and in the surrounding area, paying attention to even the slightest indication of leaks. If any leaks are found, it’s important to identify the source of the problem quickly and take the necessary steps to fix it. Whether you need to replace a part, tighten something up, or repair a component, be sure to address the issue with precision to ensure everything works safely and efficiently.

Keeping up with regular maintenance checks and addressing any issues right away is the best way to prevent potential hazards and maintain the integrity of your exhaust system.

Check for excessive structural rust

Make sure you check everything properly to catch any rust that could be dangerous. If you find any rust, you need to act fast to fix it or replace it. This will keep the structure strong and safe. If you take care of things quickly, you’ll stop the rust from getting worse and making things dangerous. You need to keep checking things regularly and fixing any problems right away. This will help keep everything strong and safe for a long time.

Challenge and assess off-ground works

It’s crucial to thoroughly check any work done above the ground to avoid any risks associated with working at high levels. We need to prioritize a comprehensive evaluation process to identify and address hazards effectively. We should strictly follow all site-specific requirements and regulations that govern work done at elevated levels.

Following established protocols diligently can ensure the safety of personnel and minimize accidents or injuries. It’s important to emphasize the significance of adhering to safety measures and procedures to avoid potential risks. We must be always vigilant in assessing risks and following guidelines to maintain a secure working environment. Consistent vigilance and compliance create a culture of safety and accountability within the workplace.

Check for interactions between exhaust systems and other components

Check the exhaust systems thoroughly for any possible contact with nearby parts. Look closely at how the exhaust system is aligned and how close it is to other elements. Find any cases where contact might happen, affecting efficiency or safety. Fix these problems quickly by removing, moving, or changing parts as needed.

Focus on accuracy in changes to get rid of any possible causes of friction or blockage. By keeping a clear and free path for exhaust flow, avoid problems and improve the function of the whole system. Regular checking and changing keep operational quality, increasing efficiency and lifespan. Constant attention to detail in dealing with contact helps a smooth integration of parts, boosting overall performance and dependability.

Look for grease falling onto or near exhaust systems

Be on the lookout for grease spills or drips that may have happened on or near the exhaust systems. Take a good look around the area to see if there’s any accumulation of grease. If you spot any source of grease leakage or spillage, make sure you address it right away to prevent any negative impact on the exhaust system. It’s important to act quickly to reduce any risks associated with grease exposure, which will help ensure the exhaust system’s optimal performance and safety.

Take steps to keep the grease away from the exhaust system to avoid any potential hazards. Keep an eye out for any grease-related issues and take action to fix them right away. Doing so will help maintain the efficiency and integrity of the exhaust system.

Check for wet areas on the exhaust

It’s super important to check the exhaust system for any wet areas that might mean there are fluids present. Take a good look at all the parts and keep an eye out for any signs of moisture or dampness. If you do spot any fluids, make sure to investigate the source right away so you can figure out what it is and where it’s coming from.

It could be coolant, oil, or something else entirely, so you need to act fast to prevent leaks or seepage. Make sure you fix the affected areas and keep the exhaust system in good shape. Keep an eye on it regularly to make sure there are no fluid-related issues that could cause damage or malfunctions. Stay ahead of the game and take care of wet areas to keep your exhaust system running smoothly and efficiently.

The key takeaway

When it comes to mechanical maintenance, the small things really do matter. Being careful and quick to deal with any issues can avoid potential hazards and keep everything running smoothly.

Whether it’s dealing with rust or cleaning up spills, every little thing helps to keep industrial systems in top shape.

So let’s keep putting maintenance first and recognize how important it is to keep everything reliable and safe in industrial operations. Working together, we can make sure that everything runs smoothly and everyone can relax.